Automatization & Robotization products

Industry 4.0 is transforming manufacturing through advanced automatization, ensuring greater efficiency, consistency, and quality control. Smart automation systems, powered by AI, IoT, and real-time data analytics, minimize human error and enhance precision in production processes. Automated quality control mechanisms, such as machine vision and predictive maintenance, detect defects early and optimize product consistency. By reducing variability and improving monitoring, automatization not only increases productivity but also ensures higher standards, making industries more competitive and adaptive in a rapidly evolving market.

Our company offers various automatized solutions for quality inspection which is the first step for Industry 4.0

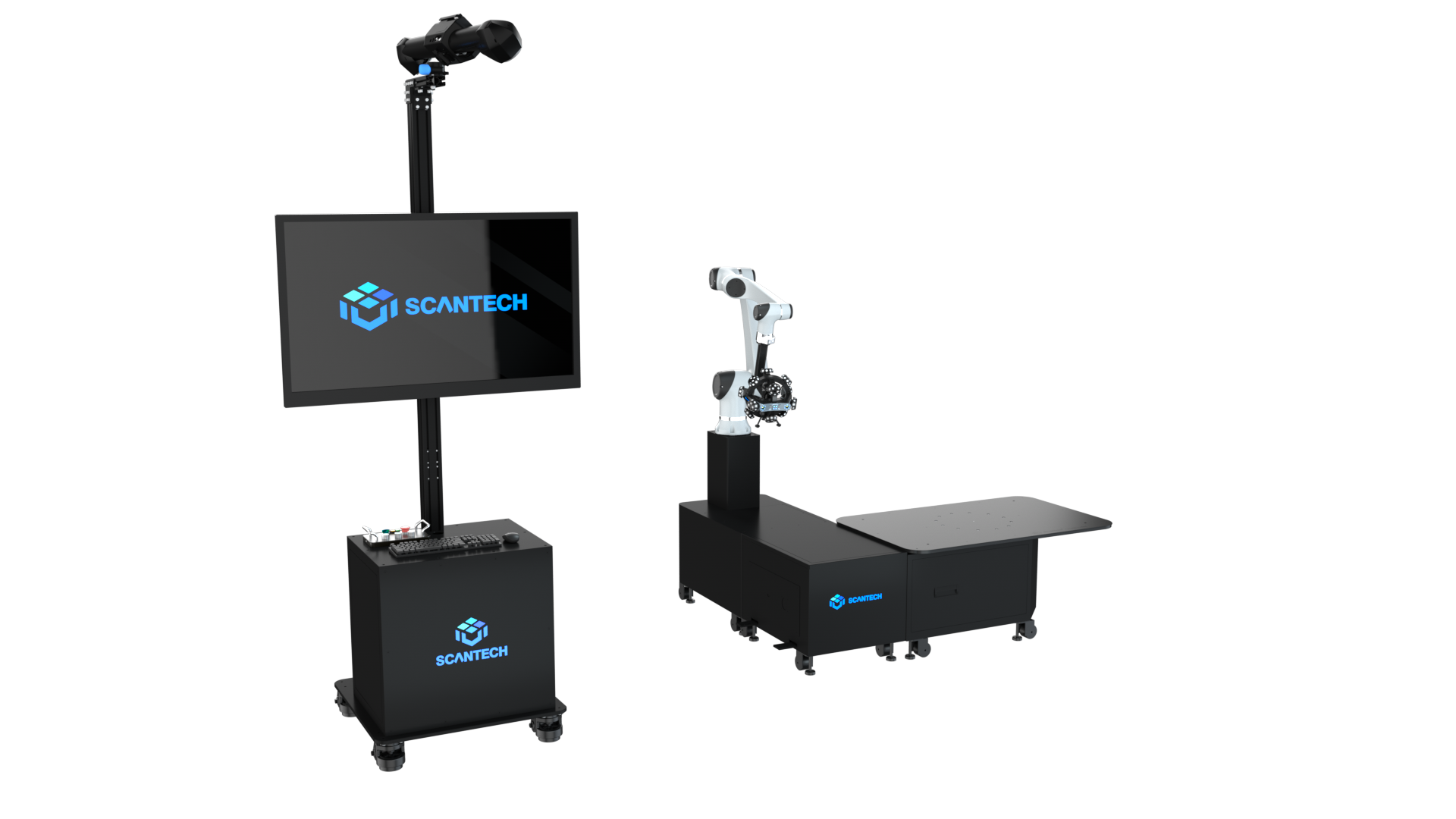

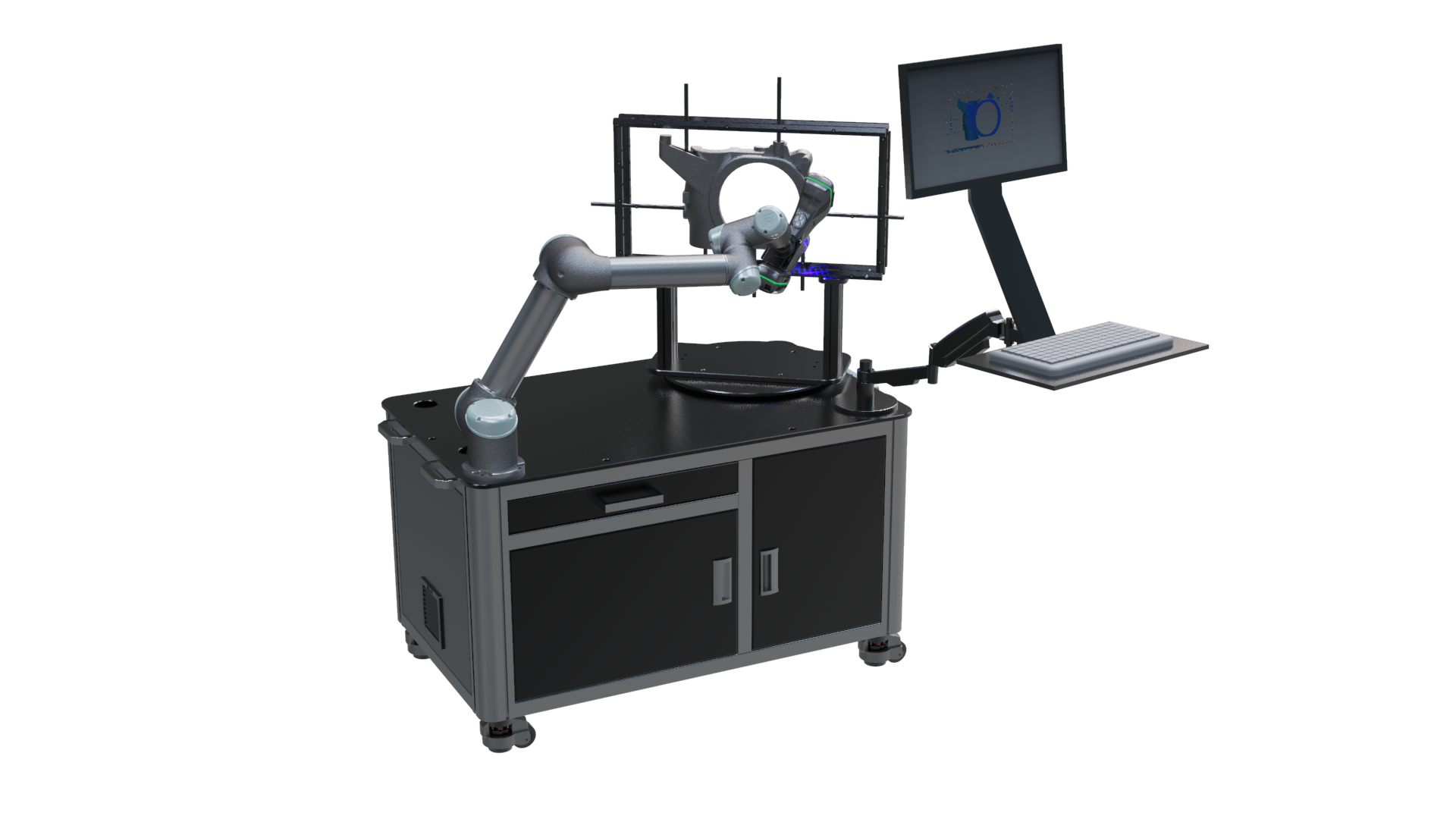

Scantech Automated 3D Measurement Systems

In the realm of factory automation, where precision is non-negotiable,.

Scantech’s automated 3D system stands out with exceptional compatibility, seamlessly integrating with our diverse range of scanners. This advanced automated 3D system ensures high repeatability and accuracy in measurements, meeting the stringent demands of industrial applications.

Coupled with specialized 3D inspection software, it empowers you to generate comprehensive inspection reports for in-depth analysis.

AutoScan-K

AutoScan-T

AM-Desk

AM-CELL

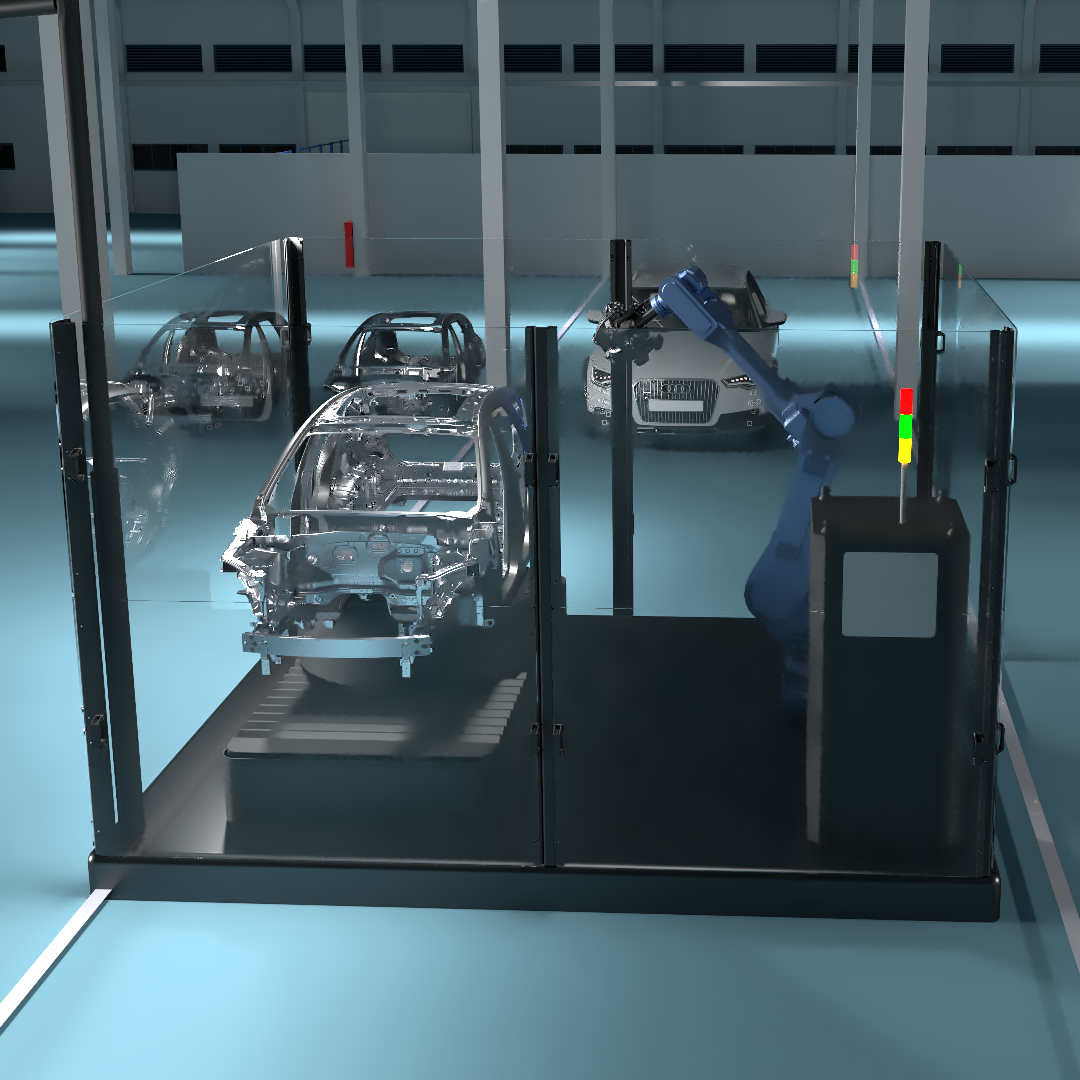

Third dimension Robotization

Vectro is a cutting-edge robotic system designed for fully automated precision feature measurement, including gap & flush, edge breaks, countersinks and more.

Industry 4.0 principles and technologies are being increasingly applied to manufacturing quality control.

Solutions like the Vectro® are bringing significant advancements in quality control processes, ensuring higher accuracy, efficiency, and productivity…

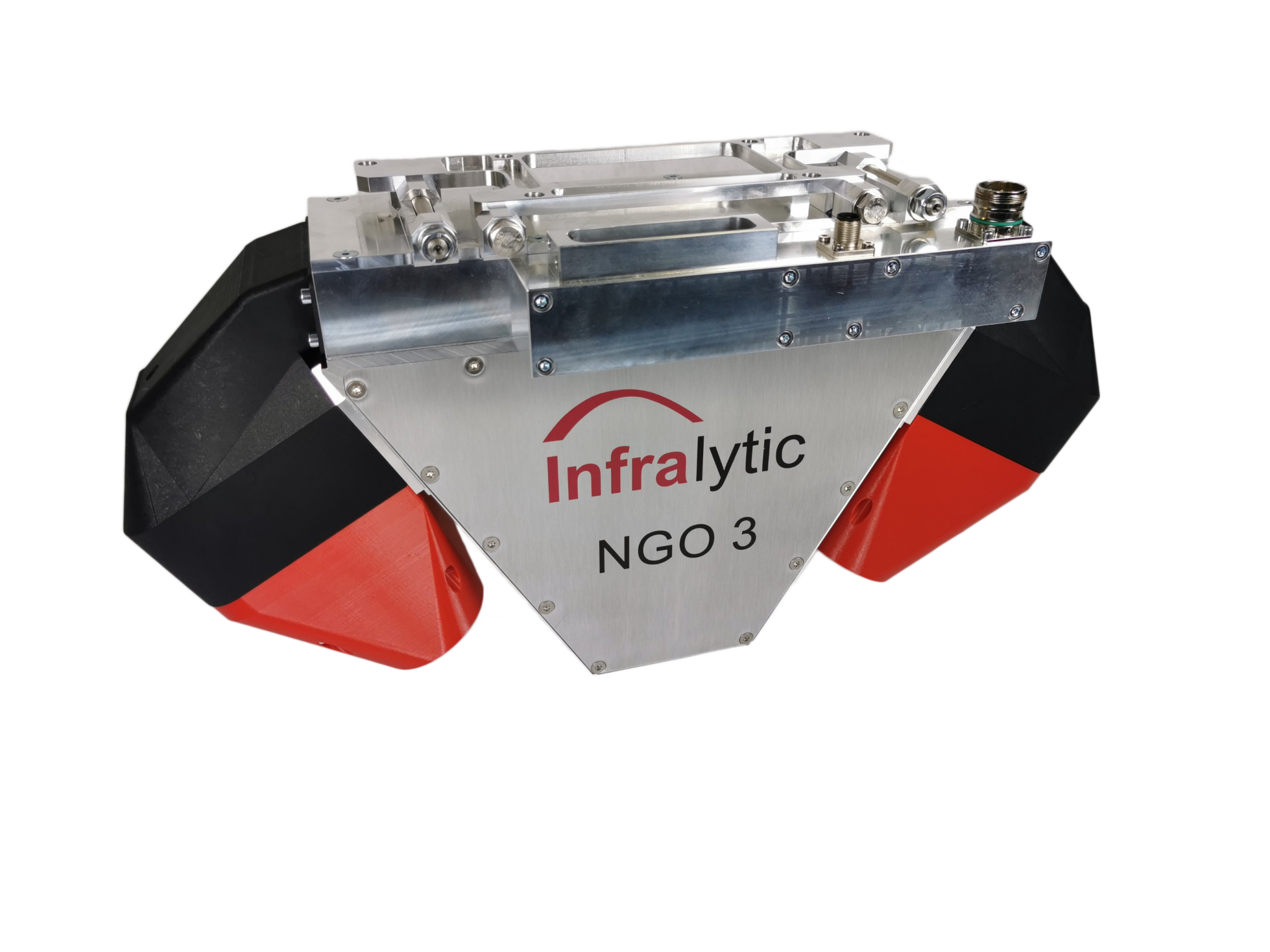

Infralytic Traversing Continuous Measurement

Infralytic is considered the most innovative developer and manufacturer in infrared measurement technology.

With over 20 years of know-how in the non-contact measurement of smear and paint layers on metal surfaces.

The inline sensors are specially designed for automated and continuous measurement, for example in conveyor systems.